ANTI-REFLECTIVE COATING GLASS

Time:2025-08-20 16:19 Number of visits:

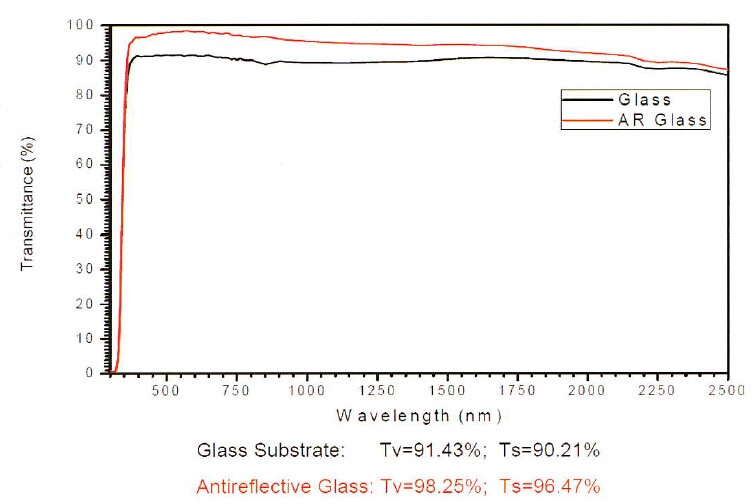

Anti-Reflective Coating Glass, short as AR Glass, is deposited by the hot-dip/immersion plating/dipplating process with anti-reflective coatings on both sides of the glass, making the light transmittance above 98% and reducing largely the reflectivity on the surface of glass compared with the original glass.

Anti-Reflective Coating Glass, short as AR Glass, is deposited by the hot-dip/immersion plating/dipplating process with anti-reflective coatings on both sides of the glass, making the light transmittance above 98% and reducing largely the reflectivity on the surface of glass compared with the original glass.

Features:

1. Reduce the reflected images, it looks like no glass, greatly enhancing the visual clarity.

2. Make the items true to nature and the colors more beautiful.

3. Further processing (to be tempered, insulated, laminated, etc.) of it is the same as the original glass.

Performance Parameters:

Optical

properties |

Transmittance |

Single side 2 layers ≥92% |

This value is the average transmittance of visible light between 380nm-780nm. Tested by visible light spectrometer. |

|

Single side 4 layers ≥93% |

|

Double sides 2 layers ≥94% |

|

Double sides 2 layers ≥96% |

Reflectivity |

Single side 2 layers≤5.5% |

This value is the average reflectivity of visible light between 380nm-780nm. Tested by visible light spectrometer. |

|

Single side 4 layers≤4.5% |

|

Double sides 2 layers ≤3.5% |

|

Double sides 4 layers ≤1.5% |

Transmittance Spectra of Anti-Reflective Coating Glass and Non-AR Coating Glass

Specifications:

Thickness: 3-12mm (with±0.2mm tolerance)

Max size: 5000*3300mm (with±1mm tolerance)

Applications:

Anti-Reflective Coating Glass is mainly used as flat display panels such as LCD, PDP, outdoor display screen, laptop display and mobile phone display and other electronic display products which need high transmittance and low reflectivity.

AR Glass can also be widely used as building glass, showcase display glass or shopwindow display glass, improving the visual effect significantly.