PARABOLIC TROUGH SOLAR MIRROR

Time£ļ2025-08-20 16:19 Number of visits£ļ

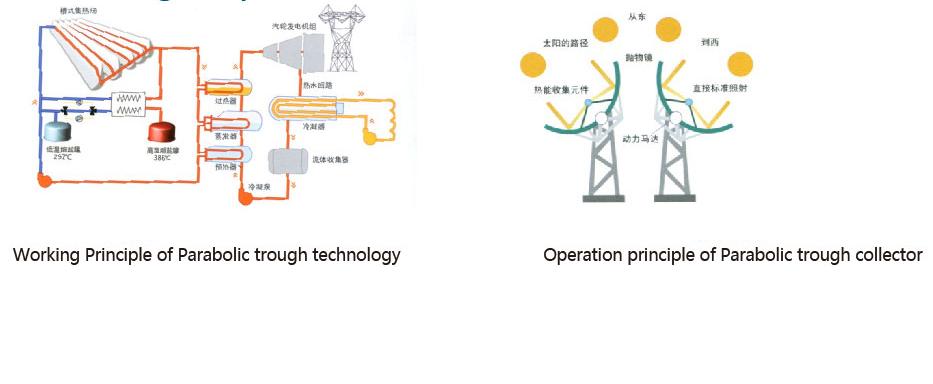

Parabolic Groove Solar Mirror will take a large area of parabolic trough solar mirrors to track the sun and achieve the maximum sunshine concentration on the collector tube, the transferred fluid in the tube will collect the solar radiation and convert the solar energy into heat, the heat will then generate steam to drive the steam turbine to generate elecricity.

Parabolic Groove Solar Mirror will take a large area of parabolic trough solar mirrors to track the sun and achieve the maximum sunshine concentration on the collector tube, the transferred fluid in the tube will collect the solar radiation and convert the solar energy into heat, the heat will then generate steam to drive the steam turbine to generate elecricity.

Features:Technical working process control:

1. Glass: high quality Low-iron float glass with min. 91% light transmittance

Glass Base PlateÔľöUltra Clear Float Glass

PropertyÔľöTempered Mirror

RadianÔľöY=X2/6600 to Y=X2/7080

light TransmittanceÔľöÔĻ•99%

Reflectivity Ôľö4mm‚Čß93%,5mm‚Čß92%

Mechanical StrengthÔľö69~90MPa

Service LifeÔľö15 to 20 years

2. Deep Processing: automatic CNN equipment to ensure high precision deep processing.

3. Bending and Tempering: using the most advanced tempering furnace from Glasstech of USA and professional testing equipment for parabolic trough solar mirrors from Germany to ensure the accuracy of glass curvature and quality .

4. Mirroring: Running professional and high-efficiency parabolic trough mirror production line:

Silver Coating: silver layer thickness≥1600mg/m2;

Copper Coating: copper layer thickness≥320mg/m2;

Painting: special UV resistance solar mirror paints (lead content≤50PPM, viscosity:25-50S, hardness:3B, Paint layer thickness≥110UM);

Curing temperature of paints: monitoring the inlet and outlet temperature strictly for each drying sector.

5. Finished Product Inspection: inspect the final reflectivity and focus of the parabolic solar mirror relying on the advance facilities.

6. Ex-factory Inspection: Every finished glass shall pass three quality inspections for all varies of articles ensuring perfect quality.

7. Packaging: All kinds of strong and seaworthy packing way can be offered, eg. wooden crates, steel racks and customized packing materials.

8.Working Principle:

9. Structure:

10. Testing:

|

Testing Contents |

Results |

Standard |

|

Resistance to Humidity |

PASSED |

DIN EN ISO 6270-2 CH 2005: 480 h |

|

Resistance to salt spray |

PASSED |

DIN EN ISO 9227 NSS 2006: 480 h |

|

Resistance to CASS |

PASSED |

DIN EN ISO 9227 CASS 2006: 120 h |

|

Stability in climatic cycling |

PASSED |

4 h: + 90°C; 4 h: -40°C;16 h: DIN EN ISO 6270-2 CH 2005: 10 cycles |

|

Weather O Meter |

PASSED |

Combination of light, temperature and water |

|

UV Resistance |

PASSED |

UVA 340 at 60°C;,39W/„é° |

Specifications:

Thickness: 3.2-5mm

Size: 1700*1641mm (outer)1501mm (inner)*5770mm (parabolic width)

1570*1900mm (outer and inner)*6770mm (parabolic width)

Applications:

Parabolic Groove Solar Mirror is widely used in Parabolic Trough Technology of the concentrating solor power (CSP) field with the earliest commercialized operation and the most mature technology.